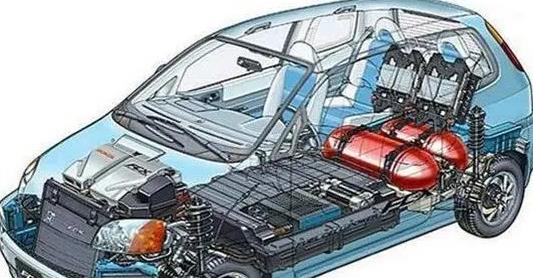

ultrasonic atomizing spraying technology is ideal for spraying expensive materials such as platinum and other precision metals in carbon black ink slurries. When these chemicals are applied to fuel cells using ultrasonic atomizing nozzles, their chemical properties are superior to hydraulic deposition, pressing, blade and paste printing methods. Therefore, ultrasonic atomizing spraying technology has been used in many fuel cell-related production processes, such as proton exchange membrane (PEM) fuel cells, gas diffusion layers (GDL), solid oxide fuel cells, electrodes and electrolyte membranes.

In general, ultrasonic atomizing atomization technology is a high-end atomization spray process, by integrating the nozzle in a multi-axis treatment system, you can control the movement of the nozzle and the substrate to obtain the most uniform coating. Without destroying the performance of the coating, precise spraying of small and complex structures will meet the needs of more high-end spraying in the future.

ultrasonic atomizing spraying equipment to achieve ultrasonic atomizing atomization precision spraying, ultrasonic atomizing spraying preparation advantages:

1. High stability

Made of high performance titanium alloy and stainless steel, strong adaptability, corrosion resistance, no pressure, no noise, no nozzle wear and blockage, high atomization particle uniformity.

2. Save materials and protect the environment

The spray impact force is small, will not cause liquid splash, can reduce the waste of raw materials and air pollution caused by reverse spray. The coating utilization rate of ultrasonic atomizing spraying is more than 4 times that of traditional two-fluid spraying.

3. High controllability

Precise control of atomization flow, low flow continuous spray, spray shape is easy to control and shape (increase spray robot arm), suitable for industrial fields. Through the combination, the atomization volume can meet any requirements of the user.

4. Easy to maintain

The liquid is transmitted to the spray head through its own gravity or low pressure pump and realizes continuous or intermittent atomization, no blockage, no wear, no noise, no pressure, no moving parts, no cooling water is required during atomization, low energy consumption, simple equipment, low failure rate, ultrasonic atomizing nozzle has self-cleaning function, daily maintenance free.

5. Widely used

ultrasonic atomizing spraying equipment is mainly used in fuel cells, thin film photovoltaic cells, thin film solar coatings, perovskite solar cells, solar cells, graphene coating, silicon photovoltaic cells, glass coating, electronic circuits and other industries. Nozzle can be applied to a variety of solutions, even sewage, chemical liquids, low viscosity oil mucus can also be atomized spray.

.jpg)

.jpg)

.jpg)

.jpg)